The use of natural gas as a primary energy source represents a major issue to global warming.

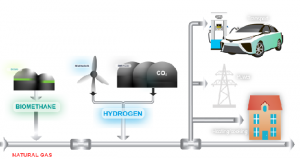

Decarbonisation of the gas grids is a possible solution, alongside electrification, to meet the climate change targets and reduce carbon dioxide emissions. This project will be the first large scale project of its kind that will tackle four measurement challenges that the gas industry need to solve before they can decarbonise the gas grid through introduction of biomethane, hydrogen-enriched natural gas, 100 % hydrogen, and carbon capture and storage (CCS). The project will cover the priority challenges within flow metering, gas composition, physical properties and safety (including monitoring of gas leaks).

The European Union set a target to reduce carbon emissions by 55 % by 2030 and become carbon neutral by 2050. To support meeting these ambitious targets the Green Deal was introduced by the European Commission, which included several aims that align with this project, including increased use of biomethane and hydrogen to reduce natural gas, and use of carbon capture and storage to reduce emissions from hydrogen and power production.

Early efforts were made to understand current measurement challenges of the energy gas industry through contacting stakeholders directly, running an online survey hosted by EURAMET Task Group on “Metrology for Energy” in 2018 (40 stakeholder entries) and via a workshop hosted by EMN Energy Gases. The common topic that was raised involved activities required for decarbonisation of the gas grid. and the following specific priority challenges were identified by stakeholders:

The specific objectives of the project are: